What is Polyethererketone? (PEEK)

April 2016

Polyetheretherketone- Chemical Compound (PEEK)

Polyetheretherketone (PEEK) is a semi-crystalline high temperature thermoplastic that offers a unique combination of exceptional performance characteristics. PEEK materials were initially made in 1977 by imperial Chemical Industries (ICI)

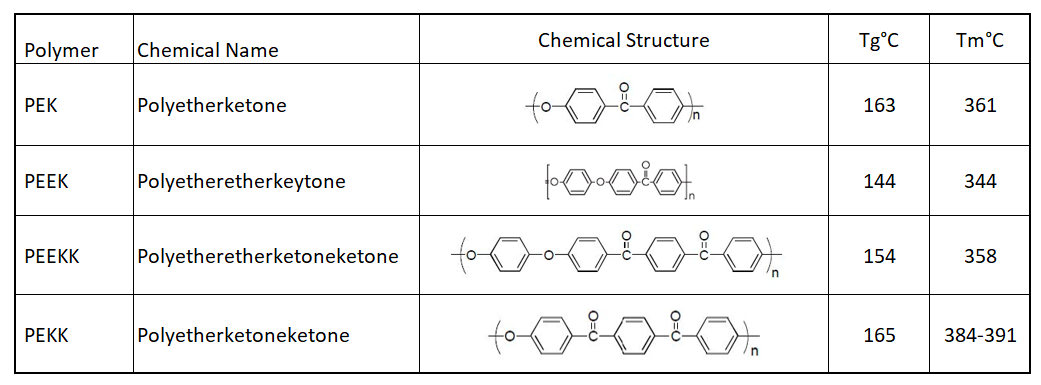

As shown in the table below, there are several polymers in the family of Polyaryletherketones (PAEK) and amongst them, polyetheretherketone (PEEK) is both most widely used and also manufactured in large scale.

Tg°C- Glass transition- the temperature at which, when an amorphous polymer is cooled below, it will become brittle and glass like

Tm°C- Melting – is a transition that occurs in crystalline polymers where the chains become a disordered liquid.

As evident from the chemical structure, PEEK contains relatively stiff aromatic polymer backbone and remains a reason for high thermal transitions. As a result, these polymers have a ‘continuous use temperature’ of around 240°C, even in hot water or steam. It possesses very good mechanical properties and outstanding chemical resistance, equivalent to Fluoropolymers.

The prescence of either linkage gives the melt processability in conventional techniques such as injection moulding, compression moulding and extrusion. The rigid and stiff chemical structure affects the crystallisability of PEEK and allows up to 48% maximum achievable crystallinity.

Achieving UL94V 0 classifications, Ohio State University heat release test, and extremely low smoke emission, makes PEEK one of the best materials with flame resistance characteristics. The softening temperatures of unfilled PEEK are around the same Tg but after filling with glass fiber or carbon fiber, the softening temperature increases significantly reaching close to the melting the point, i.e around 315-320°C.

PEEK is fully recyclable, either mechanically or as feedstock. Energy from waste can be recovered at incineration plants.

Other key features are:

- Excellent wear and surface properties can be achieved by adding various fillers, for example, our Fluorinoid® FL355

- PEEK can be blended with PTFE for applications demanding good wear and friction properties.

- Very good Fatigue resistance.

- Outstanding hydrolytic stability and radiation resistance.

- Good materials for an aggressive environment. PEEK is being used in nuclear environments, oil and geothermal wells, chemical industries, and high-pressure valves.

- PEEK is ideal for metal replacement applications mainly because of its outstanding corrosion resistance, strength, durability, wear resistance and high-temperature stability.

- FDA approved materials: FDA approval of PEEK materials finds its application in food processing industry mainly as a bearing and seals for food processing equipment.

Typical applications are:

- Implant material

- Valve parts

- Back up rings

- Valves seats

- Guide bushes

- O-rings

- Pistons

- Gears

- Compressors

- Piston rings

- Valve plates

- Centrifuges

- Dental implants

To find out how we can support your projects contact info@fluorocarbon.co.uk