Solutions

PTFE Sheet & Tape

Sheet & Tape

As one of the largest UK manufacturers of PTFE sheet and tape, at Fluorocarbon, we constantly work to ensure every product is tailored to meet customer requirements. Uniquely, we offer etching on one or both sides of the material if required.

We can provide same day delivery on all standard stock items and a fast turnaround service on non-stock items.

Using our in-house facilities, all PTFE sheet & tape products can be supplied chemically etched on one or both sides using the Fluoroetch® etching process.

PTFE Properties:

PTFE is a tough, flexible, non-resilient material of average tensile strength but with great thermal properties and excellent resistance to chemicals and passage of electric current. Withstanding temperatures of -200ºC up to +260ºC whilst retaining most of its properties, PTFE is the most thermally-stable plastic.

PTFE Sheet Uses:

Properties such as chemical inertness, outstanding weathering & heat resistance, excellent electrical insulation and low co-efficient of friction enables PTFE to be exploited in diverse range of applications such as seals, gaskets, valves, pump parts, slide bearings and chemical tank linings.

If you need to convert sizes click here

OUR RANGE

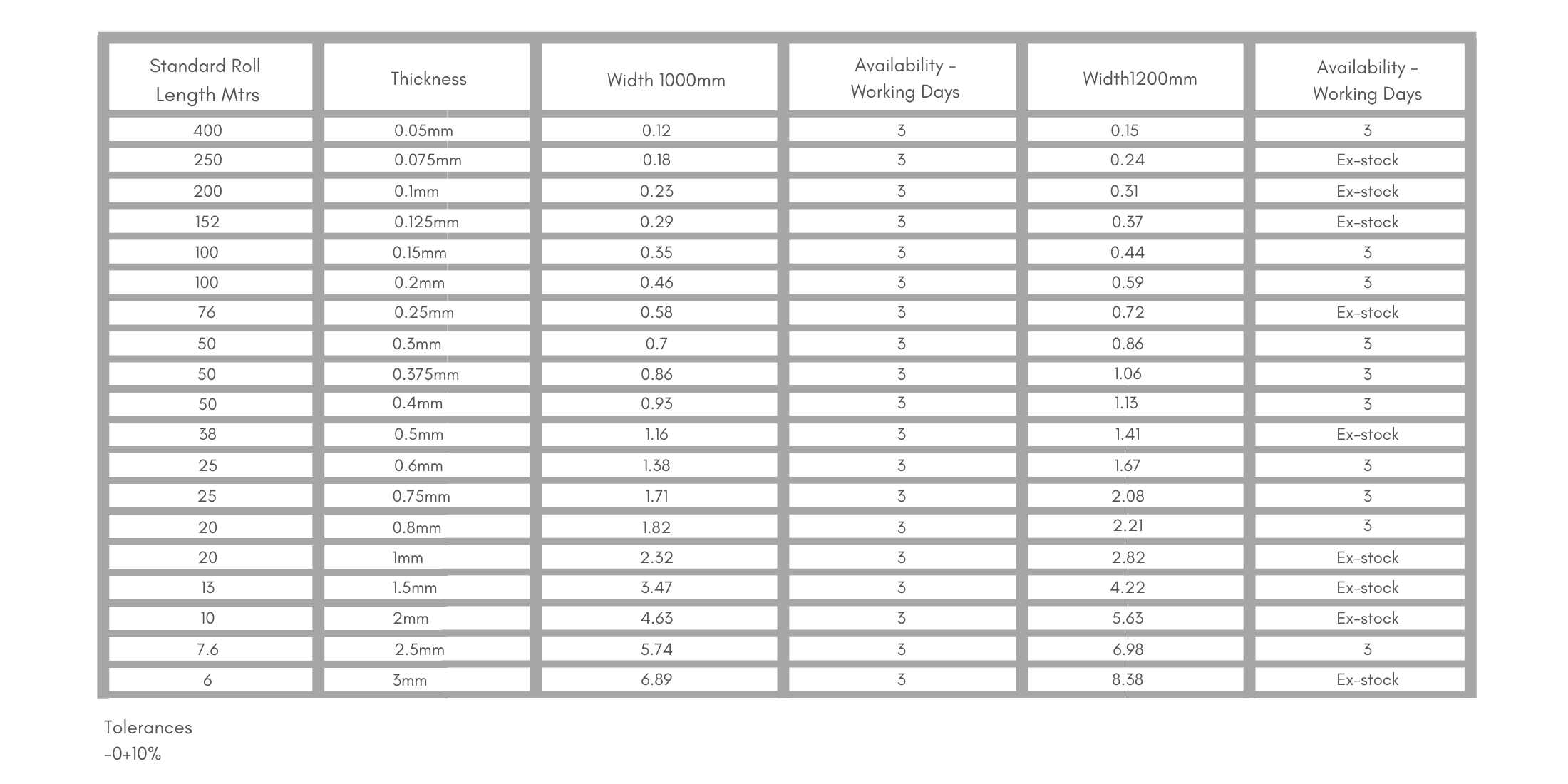

PTFE Skived Tape

- 0.1 mm to 6 mm thick to a maximum width of 1220 mm.

- Available in continuous rolls, cut sheets or slit to a specific width.

- Filled grades can be manufactured up to 1000mm wide.

We also hold a large range of Virgin PTFE billets x 1200mm long, this enables us to produce quick deliveries on tapes with thicknesses from 0.05mm to 4mm.

PTFE Moulded Sheets

- 8 mm to 100 mm thick to a maximum size 1200 mm square.

- Sheets may be supplied as cut pieces or machined in to individual shapes.

Self-Adhesive Backed PTFE Tape (Fluoroetch® SAtm)

- Four standard thicknesses; 0.13mm, 0.25mm, 0.40mm, 0.50mm.

- Continuous rolls and slit to specific widths

PTFE Dimpled Sheets

- Virgin or filled PTFE

- 3.0mm, 4.5mm, 5.0mm thick and up to 1220 square

- For bridge and Pot bearings: 4.5mm or 5.0mm thick. Supplied as sheet or machined to size.

Fluoropack® PTFE/Cork Laminate

- Available 2.5mm thick and 600 x 1200mm - for blister pack tools

PTFE Coated Glass Cloth - Available as 1000 mm wide rolls or slit to customers' requirements.

APPLICATIONS

- Electrical insulation and cable wrapping.

- Bellows and hose liners.

- Gaskets, Spectacle and Orifice plates.

- Tank and Vessel lining.

- Slide Bearings, Skidways and pipe supports.

- Bearing tape.

MATERIALS

- Supplied in a wide range of Fluorinoid® PTFE grades both virgin and filled.

- Fluorinoid® virgin PTFE grades can include modified PTFE such as Dyneon® TFM™ and filled.

- Filled grades can include such fillers as glass fibre, carbon, graphite, bronze, molybdenum disulphide and Ekonol™ both individually and in combination.

Please contact the sales team on 0161 7777 481 or 451

Etching

PTFE is well known for being a non-stick material; therefore to enable bonding to other substrates, surface modification in the form of chemical etching is required.

Using the Fluoroetch® process we offer a full in-house service of chemical etching and bonding of fluoropolymers including PTFE, PFA, ECTFE, PCTFE, FEP and TFM.

Our Fluoroetch® Sodium / ammonia process is the most effective etching medium available. The solution is freshly mixed for each specific batch to ensure the highest quality and all etching is carried out to Roll Royce RPS 407 Standard.

Capabilities

- Up to 1.2m width on one or both sides

- Bulk etching of free issue sheet and tape material

- Shapes can be selectively etched to allow bonded fabrications

- Etched sheet can be factory bonded for the manufacture of Fluoroglide® expansion bearings, slide bearings and skidways

- Etching of free-issue materials in sheet form or finished component